OPTIMIZING THE PERFORMANCE OF A DISTRICT HEATING STATION: T.E.C. DEPLOYS A TECHNICAL MEASUREMENT CAMPAIGN

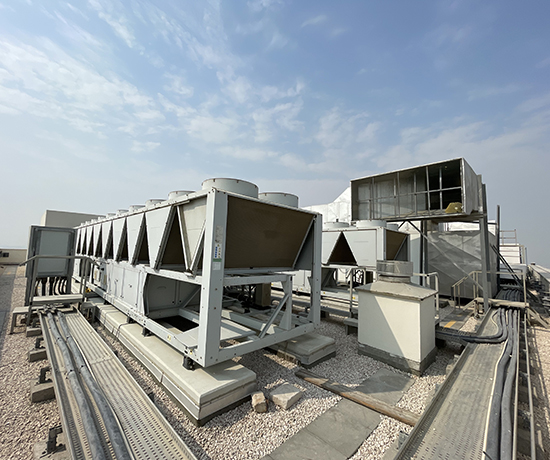

As part of a continuous improvement program, T.E.C. has launched a large-scale technical measurement campaign on a district heating station using renewable energies (RE). This project is part of our drive to optimize the overall operation of our facilities, while ensuring the reliability and durability of our equipment.

T.E.C. has launched a technical measurement campaign on a district heating station powered by renewable energies. This project is part of our drive to optimize overall plant operation while ensuring equipment reliability and durability.

MISSION OBJECTIVE :

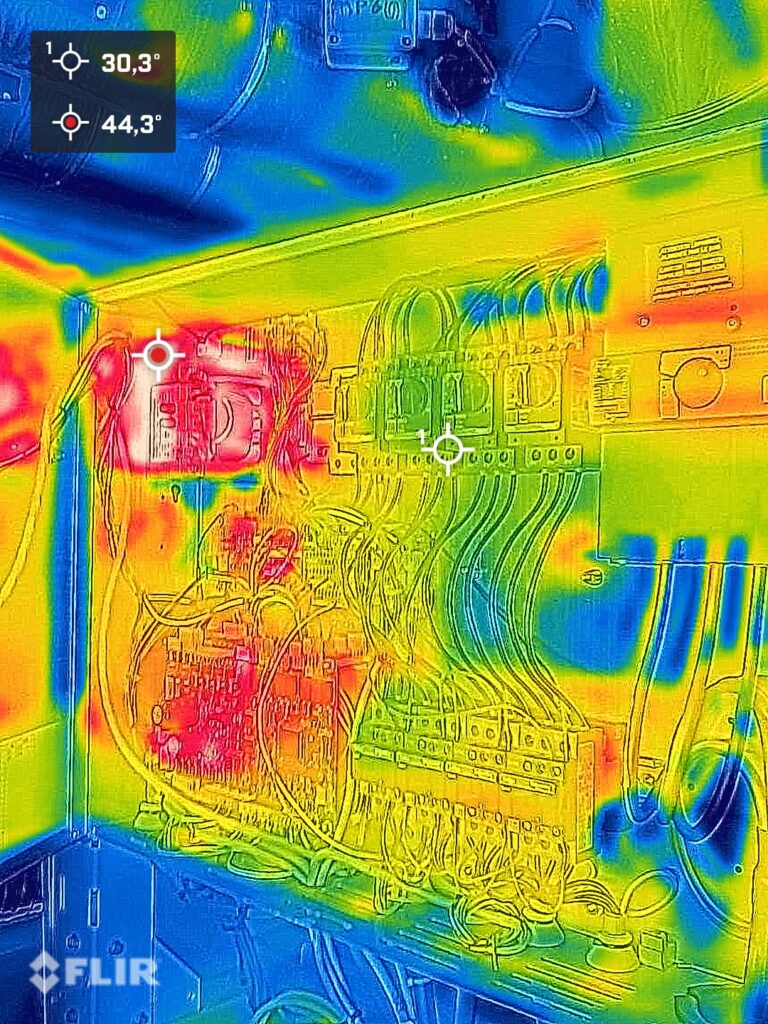

The main objective of this campaign is to check the performance of heat pumps (PAC) in operation, by recording temperatures and flow rates. These readings can be used to detect any faults in the control system or hydraulic installation.

IN-DEPTH TECHNICAL MONITORING

The mission focuses on 23 strategic measurement points. Our teams carry out a cross-analysis of the data collected by the loggers installed on site and the parameters from the heat pump controllers. This approach provides a precise diagnosis of the system’s dynamic behavior.

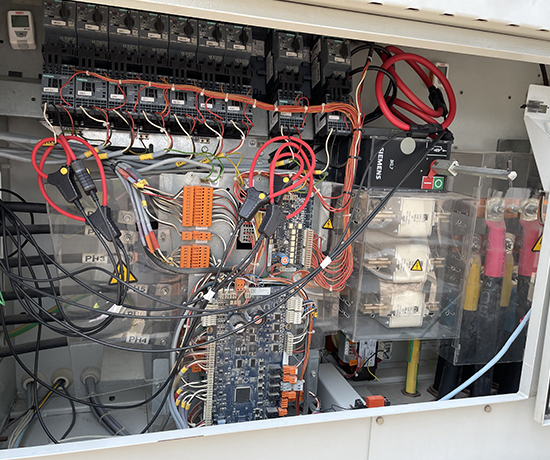

TECHNICAL EQUIPMENT DEPLOYED :

- 3 room temperature sensors

- 13 surface temperature probes

- 7 ultrasonic flowmeters

MISSION STATEMENT :

The campaign is divided into three main stages:

Preparation:

- Removal of insulation

- Installation and configuration of measuring equipment

Campaign follow-up :

- A weekly check is carried out by an Expert and a T.E.C. Technician to ensure that the equipment is working properly and to collect data.

End of campaign :

- Removal of equipment

- Site restoration

- Complete data analysis

- Drafting and transmission of final technical report

A COMPLETE AND PRECISE ANALYSIS :

This detailed analysis will :

- Identify the precise origin of any malfunctions

- Detect operating or design deviations

- Propose concrete, targeted corrective actions

A MISSION TO PROMOTE ENERGY EFFICIENCY :

This mission illustrates our daily commitment to the energy transition, through concrete solutions and field interventions. Thanks to this campaign, T.E.C. is helping to improve the efficiency and sustainability of district heating installations using renewable energies.